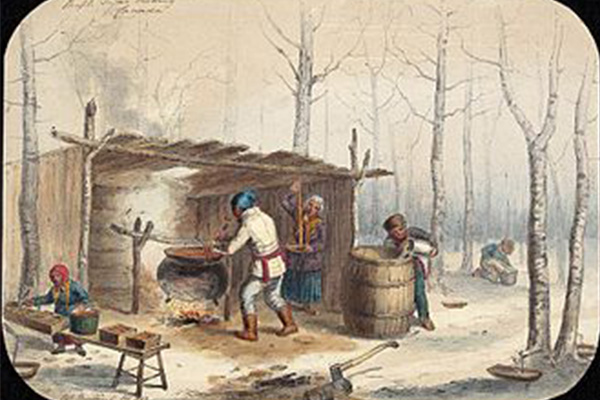

The process is quite simple once the sap has been boiled into syrup and the barrels filled but aging does take time – anywhere from 3 months by some syrup-makers to 2 years for others. I’ve read of one sugar-maker who heats the syrup in the barrel twice a month and ages it for a year.

Heated or not, it is the whiskey that has soaked into the wood fibers of the interior of the oak barrels that give the syrup its unique flavor. This whiskey remnant is known as the “devil’s cut”. The just dumped barrels we sell often have devil’s cut still sloshing around in the barrels. Cleverly, many of our customer’s further drain the barrel to obtain what’s left and what was simply overlooked during the tipping of the barrels. This whiskey is highly concentrated and can be up to 130 proof – known as “cask” strength. They then strain the liquid through cheese cloth or coffee filters to remove the charcoal particles left from the original charring of the barrels. We’ve received a number of reports that the devil’s cut makes quite a maple hot toddy … or as one of our sugar-maker friends commented, “it will get you where you want to go in a helluva hurry!”